- Chromatography

- Environmental

- Laboratory

- Analytical Measurement and Testing

- Automation and Software

- BioScience

- BOD

- Centrifuge

- Chemical Reactors

- Cleaning and Sterilisation

- Conductivity

- COVID-19 Safety Equipment

- Dissolved Oxygen

- Distillation, Separation, Filtration

- Environmental Soil-Water-Food Analysis

- Filtration

- Gas Generators

- General Laboratory Consumables

- Glassware

- Heating and Cooling Technology

- Ionselective

- Isolation Chamber

- Lab Consumables

- Lab Furnishings

- Labware

- Life Sciences

- Liquid Handling

- Microbiology

- Multi-Parameter

- Occupational Safety

- Optical instruments and Microscopes

- ORP, Redox

- pH

- Photometry

- Powder Flow Testing

- Sample Preparation

- Spectrafuge

- Spectroscopy

- Stirring, Shaking, Mixing

- Tablet Testing

- Texture

- Titrator

- Turbidity

- Vacuum Technology

- Viscosity

- Water Purification System

- Weighing

- Life Science

- promotions

- Ultra Violet Sanitisation

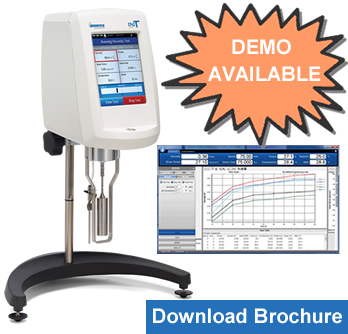

DV2T Touch Screen Viscometer

The New DV2T provides all the features of a DV-II Plus Pro but with more built-in features such as enhanced security, the ability to download/upload programs through flash drives, customise speed sets, data averaging, and a 5-inch touch screen that quickly allows data input and conveniently displays test data. It also offers powerful new programming capabilities and results analysis including data averaging and QC limits with alarms.

The new user interface provides enhanced security with customisable user levels & password access to comply with regulatory requirements such as 21 CFR Part 11.

Features and Benefits of DV2T Touch Screen Viscometer

5-inch full colour, touch screen display supports multiple languages

Displayed info includes: viscosity (cP/mP·s), temperature (°C/°F), shear rate/stress, % torque, spindle/speed, step program status

Enhanced Security with customisable user access, date/time stamp file, password access, portable log-in settings

Built-In options include timed tests, data averaging, programmable QC limits/alarms, customisable speed/spindle lists, on-screen data comparison

Magnetic Coupling for attaching the spindle to the viscometer

Auto range shows maximum viscosity measured with any spindle/speed combination

USB PC interface provides optional computer control and automatic data-gathering capability

Front-facing bubble level for convenient viewing

Built-in temperature probe

Accuracy of ±1.0% of range with displayed test data

Repeatability of ±0.2%

NIST traceable viscosity standards available

Measuring Capabilities of Laboratory Viscometers/Rheometers

Each of our standard Laboratory Viscometers/Rheometers is supplied with an internal spring used to calculate the viscosity of a material. These springs have different measuring capabilities:

LV is for low-viscosity materials and can measure the thinnest substances. Typical examples include inks, oils, and solvents.

RV is for medium viscosity materials, those with a viscosity higher than that measurable with an LV torque. Typical examples include creams, food, and paints.

HA is for higher viscosity materials, those with a viscosity higher than that measurable with an RV torque. Typical examples include gels, chocolate, and epoxies.

HB is for even higher viscosity materials, those with a viscosity higher than that measurable with an HA torque spring. Typical examples include asphalt, caulking compounds, and molasses.

Additional special springs are also available upon request.

Comprehensive Learning and Maintenance Resources

Explore our Education Section for in-depth resources on viscosity and rheology, including detailed discussions on Newtonian and non-Newtonian fluids. Visit our Viscosity FAQ page for expert answers to common questions and insights into how Brookfield instruments can enhance your production process.

To maintain the DVNext Rheometer's precision and extend its lifespan, we recommend annual calibration and maintenance through Brookfield or an authorised dealer. This ensures your instrument meets stringent standards and continues to deliver optimal performance. Visit our Calibration Services page for more details on our offerings.

|

To find out more: |