Product Categories

The Quality Of Seal Strength

A great contributor to the success of the food industry is the emerging science of packaging. Packaging plays a key role to primarily protect the food product against physical, chemical, and mechanical damage as well as contamination. Packaging has also evolved into a key marketing industry and how manufacturers can differentiate their products from those of their competitors. In this article, we are going to observe two examples of the seal strength and peel strength of packaging materials in the food industry.

Packaging Seal Strength

Packaging products in sachets is a quick and straightforward way for consumers to obtain their product, many condiments, such as ready-made sauces and dressings, are packaged into sachets. New products can be promoted in the marketplace with the right choice of packaging materials. Maintaining the cleanliness or sterility of the product throughout all stages from manufacturing to transportation to storage on shelf until the consumer makes the purchase is also the more important function. The seal must be assessed before manufacturing process begins to ensure the successful packaging of their products.

A Texture Analyser is used to measure the quality of the seal purposed to provide a barrier that protects the product from its external environment. Capability of the seal to resist separation is measured by using the tension testing method. A typical example of a test device used for this type of tension testing is the Dual Grip Fixture (TA-DGF). See the image below.

The Dual Grip assembly is a multipurpose fixture used in tensile testing. The grips are 25mm wide and fitted with rubber inserts to maximise the secure clamping of the packaging seal sample. These grips can hold rectangular samples up to 5mm in thickness and are used to pull a packaging seal sample apart.

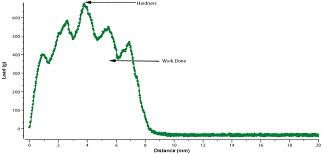

Image 2 is a typical graph from a tension test using the Dual Grips with a Texture Analyser to measure the seal strength of a black pepper sachet:

Image 2: Load verses time graph for the seal strength of a pepper sachet

As the tensile force increases, the packaging seal begins to weaken at various points seen by fluctuations in the load values on the graph. The maximum force value on the graph is a measure of the force required to initiate tearing at the packaging seal. When the maximum tension force is reached, the packaging seal begins to tear away more easily, as seen by the gradual drop in tension load until total separation when the load value drops to zero.

The mean load indicated on the graph is the average force required to weaken and tear the packaging seal.

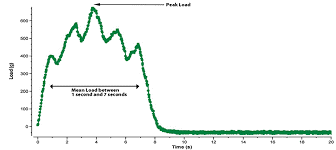

Image 3 is presenting a typical load vs. distance graph for the same tension test using the Dual Grips with a Texture Analyser to measure the packaging seal strength of a black pepper sachet. This is an alternative option for displaying the test information. Here the work done to weaken and tear the seal is measured as the area under the graph.

Image 3: Load verses Distance graph for the seal strength of a pepper sachet

A summary of the results for one sachet is shown in the following table:

|

Sample |

Peak Load (g) |

Mean Load (g) |

Work Done (mJ) |

|

Black Pepper Sachet |

672 |

497 |

13.3 |

Peel Strength of Packaging Seal

Peel tests measure the adhesive or bond strength between two materials. Typical examples include films and backing materials for adhesive patches amongst others. A peel test is performed when a tension load or force is applied to the material under investigation in one of three ways as listed below:

- Pulling a flexible material away from a non-flexible material both of which are held vertically.

- Pulling a flexible material (positioned vertically) away from a non-flexible material (positioned horizontally).

- Pulling two flexible materials axially apart from each other. This is known as the “T” peel test.

A typical example of a peel test fixture is the General Peel Jig (TA-GPJ). The fixture is designed such that it can perform 0°, 45°, and 90° peel tests based on the position of the fixture relative to the base of the instrument.

The flexible material (backing, film, etc.) is inserted into the grip (or partially peeled prior to inserting into the grip) and the product container (e.g., the non-flexible material) is locked into position on the fixture platform using the thumb screws in preparation for the test. The sample holder straps the product container in place at the neck region, thus fastening the item into a fixed position for testing. The Texture Analyzer is connected to the grip by a string and applies a gradually increasing tensile force to the flexible material. The protective material (e.g., backing or film) is peeled away from the product container. The force required to peel the flexible material away is a direct measurement of bond strength between container and seal.

A peel test is vital in quality control since it allows you to analyze the seal integrity and product safety. The tests also ensure the proper functioning of the adhesive seal by ensuring that the seal is strong enough to keep the product sterile, yet easy enough to peel without causing spillages or inconsistencies in peel strength.

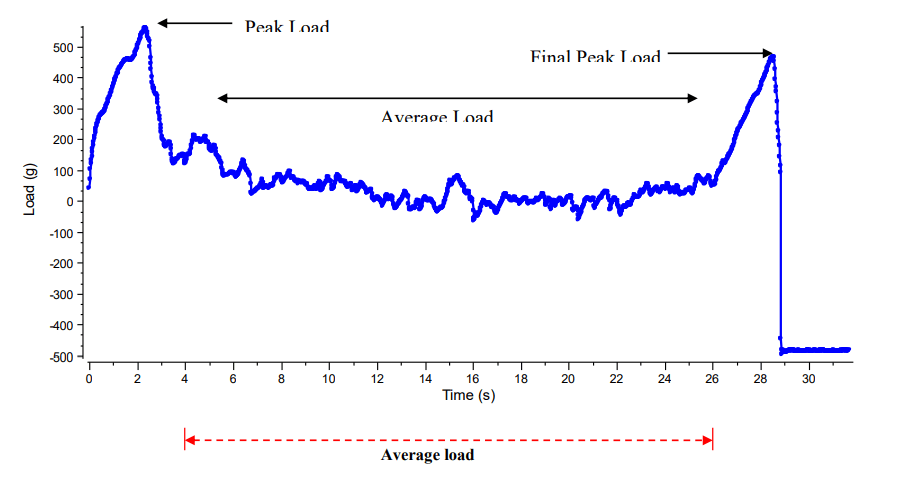

The graph in Image 5 shows data taken from a 0 o peel test of a seal on a yogurt bottle using the General Peel Jig.

The two peaks on the graph represent the force necessary to break the rim-seal contact at the start of peeling and then again when the seal finally lifts off the container at the end of peeling. The dotted line on the graph is the force required to continue peeling at a constant force and is calculated to be the average peak load. The fluctuations in the actual data on the graph indicate the small variability in peel strength as the seal is removed.

Load verses distance graph for peel strength test of seal from a yogurt drink bottle

The image above shows the graph for an alternative option to display the test results. The graph shows the distance travelled by the tensile grip throughout the peeling process. The average peak load can however only be calculated from the load vs. time graph in Image 5 as the calculation involves a defined time interval.

A peel test will reveal any issues that may develop because of the packaging seal's quality. This data can be used to require the package engineering team to improve seal strength. If the peak force is extremely high at the start of the test followed by a rapid drop in force, this indicates the possibility of spillages for low viscosity products as the user attempts to peel off the seal from the container. Moreover, large fluctuations in the force to continue peeling will also indicate poor seal quality with inconsistencies in peel strength and spillages will also be likely to occur. The advantage of this peel test is that it can be extended to all types of rectangular, oval, and circular containers.

The following table summarises the results from the peel test.

|

Sample |

Peal Load (g) |

Average Peal Load (g) |

Work (mJ) |

|

Yoghurt Bottle |

561 |

35.7 |

14.43 |

Conclusion:

Two methods for determining the amount of force needed to open packaged foods have been demonstrated. Texture Analysers are highly flexible pieces of equipment that can come with a variety of fixtures to perform a battery of tests on packaging materials. Any food laboratory that wants to be competitive will use a Texture Analyser instrument to verify not only the consistency of their product, but also the integrity of their food packaging.

Want to find out more?

Do you have any questions about the Quality of Seal Strength in the Food Packaging Industry? If so, contact our experts in this field here at Lab Unlimited today!

Contact us Today! |